1. Protective effect: improving weather resistance and corrosion resistance

Aluminum alloy itself has good corrosion resistance, but it may still oxidize if exposed to the outdoors for a long time (rain, salt spray, humid environment). Baking white paint forms a dense protective layer, isolates air and moisture, and delays the oxidation of aluminum. White baking paint usually adds anti-UV ingredients to reduce the powdering and cracking of the paint caused by direct sunlight, and prolong the service life of Bracket for Outdoor Awning. The baking paint process makes the coating more firmly bonded to the aluminum substrate, adapting to high temperature exposure or low temperature freezing, and not easy to peel off.

2. Aesthetic effect: visual optimization and environmental adaptation

Due to its excellent optical properties, white has multiple advantages in the application of Bracket for Outdoor Awning. From the perspective of visual aesthetics, white has a light reflectivity of up to 80%-90%. This high reflective property can effectively weaken the inherent industrial mechanical feel of metal brackets, making them more naturally integrated into various architectural environments. White brackets can form a harmonious color transition with common building exterior wall coatings and standard awning fabrics, which will not appear abrupt and can improve the coordination and aesthetics of the overall facade.

3. Functional optimization: heat reflection and practical design

The heat reflection performance of the white coating is based on rigorous optical principles. Its excellent 80-95% solar spectrum reflectivity covers the key visible light band and near-infrared region, which is far higher than the 20-40% reflection level of dark coatings. In practical applications, this heat reflection property can significantly reduce the surface temperature of the metal substrate by 30-45℃. This temperature difference data not only meets the EN ISO 13732 hot surface safety standard to avoid burns to users, but more importantly, it can effectively delay the thermal fatigue of aluminum alloy materials.

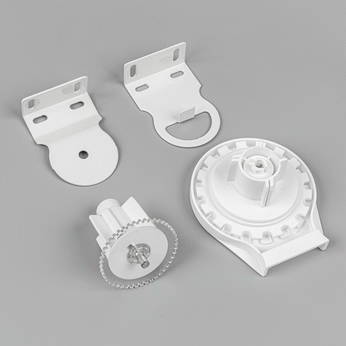

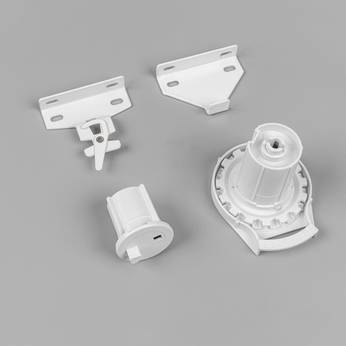

4. Process advantages: baking paint vs ordinary spray painting/anodizing

In view of the complex structural characteristics of awning brackets, modern baking paint technology shows excellent adaptability. Electrostatic spraying technology can achieve complete coverage of 0.2mm narrow gaps, and the film thickness deviation is controlled at a precision level of ±5μm. Through the innovative "edge effect" control technology, the film thickness of the corners is ensured to reach more than 90% of the flat area, providing full protection for the most easily worn parts of the product.

Note: Limitations of baking white paint

Despite its strong weather resistance, extreme climates (such as acid rain and sandstorms) may still cause paint wear. It is recommended to check regularly and touch up when necessary. Although white is universal, if the user needs to match the color of a specific building, it is necessary to confirm whether custom color services are provided.

EN

EN  中文简体

中文简体 get a free quote

get a free quote

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)