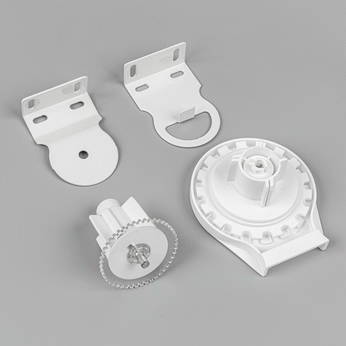

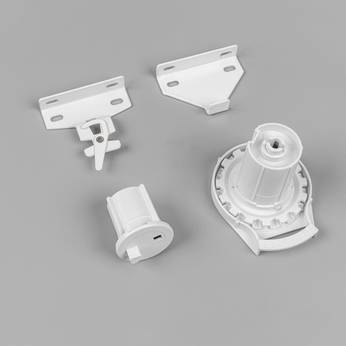

Roman blinds, with their timeless charm and practical functionality, owe much of their smooth operation to the intricate internal components housed within the cord lock mechanism. In this exploration, we pull back the curtain to reveal the precision engineering that defines these internal Roman Blind Components.

At the heart of the cord lock mechanism lie gears, meticulously designed to facilitate the controlled movement of the blind. These gears work in tandem, translating the force applied to the lift cords into a synchronized motion that allows the blind to ascend or descend with ease. The precision of these gears is crucial in ensuring a seamless and reliable operation every time the blind is adjusted.

Springs play a pivotal role in maintaining tension and supporting the overall functionality of the cord lock mechanism. When the blind is raised, springs absorb and store potential energy, ready to release it when the blind is lowered. This energy transfer contributes to the smooth and controlled movement of the blind, preventing sudden drops and ensuring a gradual descent.

In the intricate dance of the cord lock mechanism, pulleys act as guiding partners. They redirect the path of the lift cords, ensuring that the force applied is distributed evenly across the mechanism. This even distribution is fundamental to preventing uneven wear and tear, extending the lifespan of the blind, and contributing to its long-term reliability.

The locking device is the linchpin of the internal components, responsible for holding the lift cords securely in place when the blind is at the desired height. This component engages with precision, creating a stable lock that prevents any unintended movement. The efficiency of the locking device is a testament to the meticulous craftsmanship that goes into the design of cord lock mechanisms.

Bearings are integral components that reduce friction within the cord lock mechanism. As moving parts interact, bearings ensure a smooth and fluid motion, minimizing resistance and preventing wear. This feature not only contributes to the overall performance of the blind but also enhances its longevity by reducing the impact of friction on key components.

Some advanced cord lock mechanisms incorporate tension adjusters, allowing users to fine-tune the resistance of the cords. This customization enables individuals to set the blind to their preferred level of tension, providing a personalized touch to the operation of Roman blinds.

The materials used in crafting these internal components are crucial for ensuring durability and longevity. High-quality plastics, metals, and alloys are commonly employed to withstand the regular wear and tear associated with raising and lowering the blinds. This choice of materials not only enhances the performance of the cord lock mechanism but also contributes to the overall robustness of the Roman blind.

EN

EN  中文简体

中文简体 get a free quote

get a free quote

.jpg?imageView2/2/w/346/format/jp2/q/70)

+middlebracket.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)

.jpg?imageView2/2/w/346/format/jp2/q/70)